The state of our industry is once more in flux. Solid fixed operations absorption is becoming critical yet again as a looming front-end plateau becomes a reality. As we’ve discussed in parts 1 and 2 of this blog, creating individual training paths and growing technicians from students to top employees are key ways to keep highly qualified technicians in your shop. Now, we’ll look at how creatively designed compensation plans can not only retain your back end’s most valuable investment, but also motivate them to produce more so you get the biggest return on that investment.

Hourly and flat-rate industry-standard pay plans are well and good. But, to get technicians to stay, turn more hours, increase the bottom line, and secure the dealership’s financial stability through fixed operations absorption, it’s time to look into some outside-the-box compensation.

- Inspect and Reward What You Expect: Performance Levels

Track efficiency, productivity, and proficiency. Make sure your technicians know what the dealership’s benchmarks are for each area and their individual expected contribution. Align compensation to these goals and set no limits when a technician exceeds the dealership standard. It is a great way to show your technicians their expertise and performance is recognized and rewarded. They perform at a higher level, producing more hours in a day and making the bottom line a lot healthier—a definite win-win.

- Make CSE/CSI a Priority

Be sure technicians understand their direct impact to CSE/CSI beyond just “Fixed Right First Visit” on survey results. And, help them realize the correlation between the customer voice and retention. Technicians need to be responsible for their part in the dealership’s processes that are intended to boost customer satisfaction. The best spent CSE/CSI budget isn’t expended on compensating customers after a less than stellar experience. Instead, spend it on technicians and the parts and service team to ensure those scores reach the top and stay there.

Share the dealership’s goals and satisfaction reports so technicians can monitor their individual performance. And like advisors and managers, bonus technicians for above target CSE/CSI performance.

- Get Creative With Spiffs and Bonuses

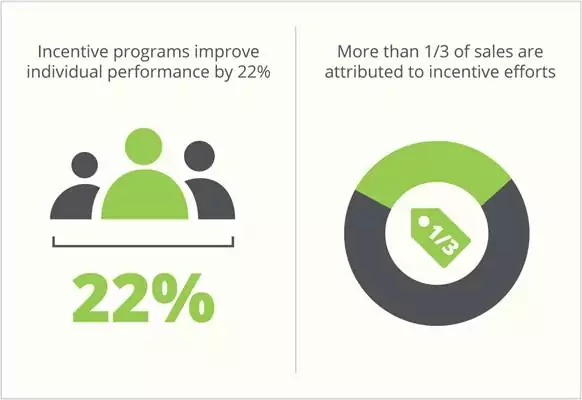

Let technicians earn a little extra money while you get additional sales. Looking to boost inspections or sales on a particular part? Just purchased a truck load of tires from your OEM’s promotion? Perhaps that $55,000 new alignment machine needs to start paying for itself? Spiff your technicians to get them to focus on checking and recommending appropriate upsells.

Cash is king! If paying your spiffs in dollars, pay the winners in cash instead of a check. Cash that can be spent immediately without a trip to the bank simply means more and feels like a better reward. Remember, spiffs don’t always have to be monetary. Paid time off, lunch off site with management, OEM apparel, gift cards for tools, etc. are all great motivators.

Change it up. Running the same spiff program with the same rewards will eventually lose its luster. Offer a new program each month with different types of rewards. One month, spiff anyone who upsells the special. The next, spiff only the top performers. Use pull boards and other visual incentive props to engage employees. Get creative!

Don’t be crippled by the idea that “I can’t pay more money for employees that already make top dollar.” Do the calculations. Adding some well-placed incentives will motivate your technicians to work harder, produce more sales, and, best of all, improve overall morale and technician retention.

In part 4 of this blog, we will discuss the ways to improve the technician/manager relationship. Stay tuned!

Explore more resources

Maximize Efficiency & Customer Satisfaction in Your Dealership

This article aims to provide you with the knowledge necessary to optimize your dealership’s performance and ensure delighted customers every…

One Family’s Journey in Automotive

Black History Month is a powerful reminder to all Americans and the world of our undeniable impact on this country….

How to Control Dealership Expenses with a DMS?

Managing a balance sheet has always come with challenges, but dealership cost control is growing increasingly complicated.

Stay up to date

Subscribe to get the latest auto industry insights from Autosoft experts